🔥 Why Insulation Matters

- Better heat retention — Slows heat transfer through walls, roof, and floor so the heater works less and sessions stay stable.

- Faster warm-up — A well-insulated structure reaches target temperatures quicker, even in cold weather.

- Moisture protection — A sealed foil vapor barrier limits condensation in the wall cavity, reducing mold and rot risk.

- Lower operating costs — Use less electricity or wood to maintain heat, saving money over the life of the unit.

- Longer lifespan — Reduced thermal stress and moisture ingress help the building envelope last longer.

Planning a winter build or upgrades? Read Do Outdoor Saunas Work in the Winter?

🧱 Best Materials for Saunas & Hot Tubs

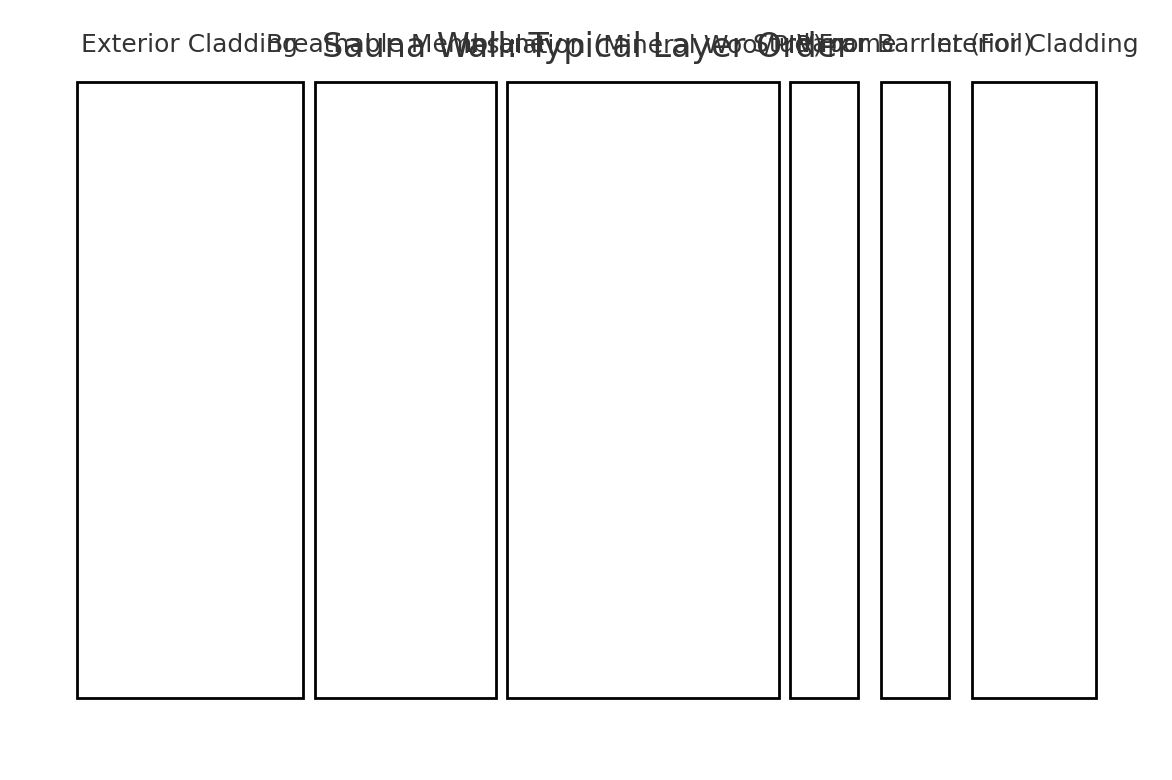

Mineral Wool (Rock Wool)

Excellent temperature resistance, non-combustible, and stable under humidity. Always pair with a sealed foil barrier.

PIR / Foil-Faced Rigid Boards

High R-value per thickness and integrated foil facer. Ideal where wall depth is limited. Ensure boards are rated for higher temperatures.

Vapor Barrier (Aluminum Foil)

Installed on the warm side of the assembly to stop water vapor from reaching cold surfaces. Seal every seam, corner, and penetration.

🏗️ Design Tips that Save Energy

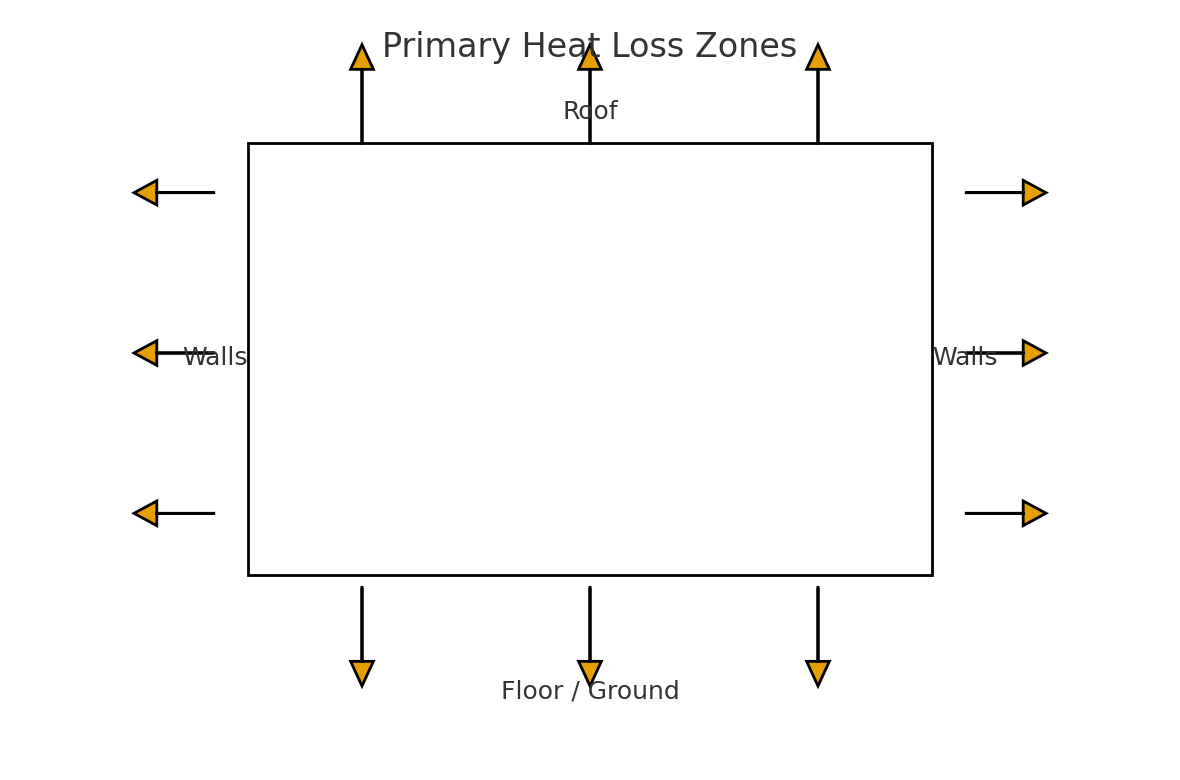

- Prioritize roof and upper walls where heat accumulates.

- Break thermal bridges at studs, corners, and fasteners using continuous foil facer or battens.

- Seal doors and glazing with quality gaskets; consider double-glazed windows.

- Vent smartly — provide controlled fresh air without uncontrolled leaks.

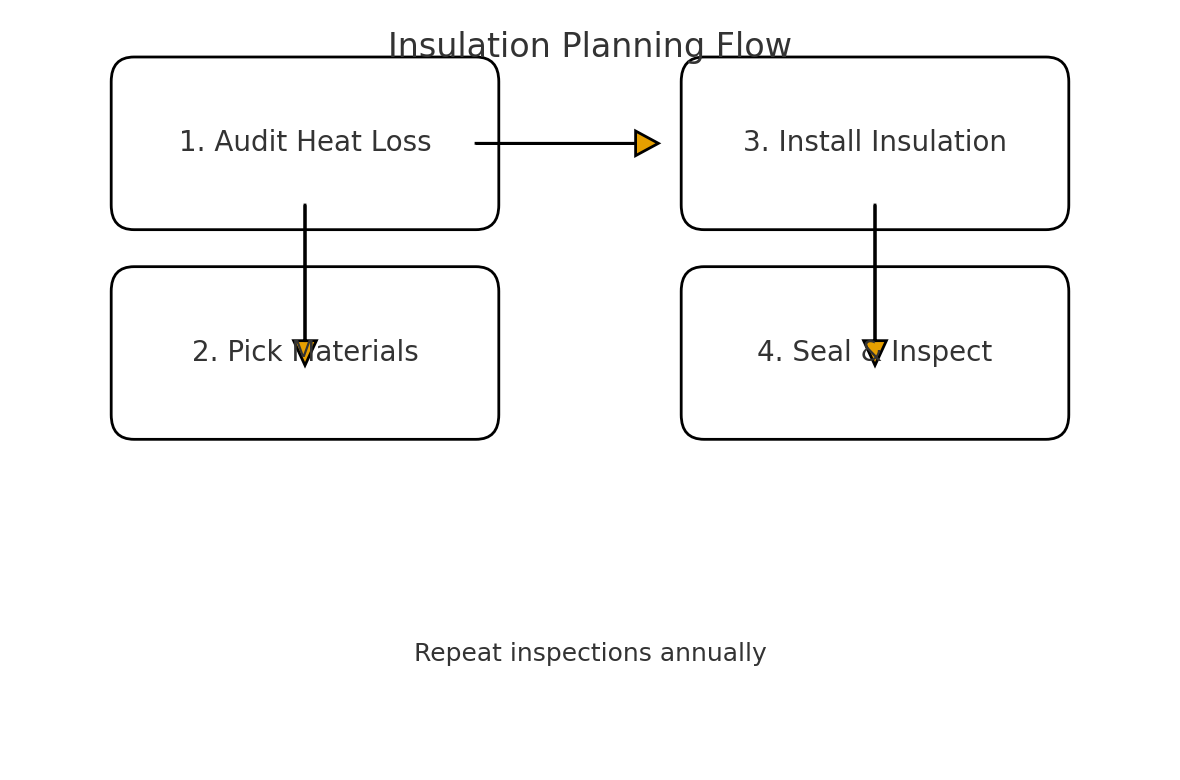

🔧 How to Install Insulation (Step by Step)

- Audit heat loss: measure surfaces and identify gaps, joints, and penetrations.

- Cut and fit insulation: avoid compression and voids; friction-fit or board-fit snugly.

- Add foil vapor barrier: install on the warm side; tape seams and seal all edges and penetrations.

- Re-clad interior: reinstall interior cladding; ensure vents and heater clearances meet manufacturer guidance.

- Test & monitor: perform a trial heat-up; check for drafts, cold spots, or condensation and correct.

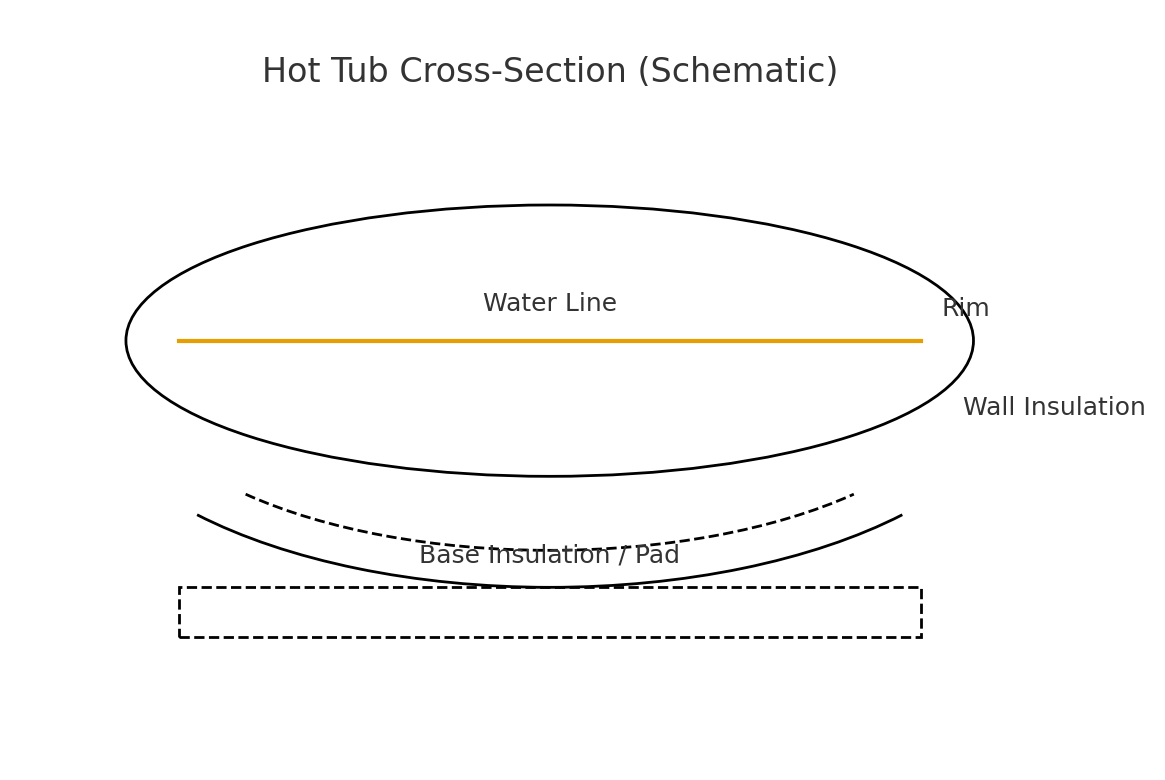

🛁 Hot Tub-Specific Insulation Notes

Fully wooden tubs can’t be insulated within the wall staves themselves, but hot tubs with polypropylene or fiberglass liners can incorporate wall, base, and lid insulation effectively. Typical approaches use polystyrene (polypropylene shells) or polyurethane foam (fiberglass shells), with 4 cm average thickness—more in walls and base. For examples and photos, see insulated models in our product posts and gallery.

📌 Final Thoughts

Insulation isn’t just an upgrade—it’s a must-have for outdoor saunas and hot tubs in most climates. Get the basics right (layers, sealing, ventilation), and you’ll enjoy faster heat-ups, stable sessions, and lower bills for years. Keep it efficient with seasonal checks and smart maintenance.

Frequently Asked Questions – Sauna & Hot Tub Insulation

Why is insulation so important for an outdoor sauna or hot tub?

Insulation keeps heat inside, protects the structure from moisture, shortens heat-up time, and significantly reduces running costs. It also extends the lifespan of the building and equipment.

Which insulation material is best for saunas?

Mineral wool (rock wool) and PIR foil-faced rigid boards are the best options. Both withstand high temperatures and humidity when combined with a properly sealed aluminum vapor barrier.

Do I really need a vapor barrier?

Yes. A foil vapor barrier is essential on the warm side of the wall to prevent moisture from entering the insulation layer, which would otherwise cause mold, rot, and heat loss.

Can a fully wooden hot tub be insulated?

Traditional all-wood tubs cannot be insulated inside the wall staves. However, hot tubs with fiberglass or polypropylene liners can be fully insulated in the walls, base, and under the cover.

Which part loses the most heat?

The roof loses the most heat, followed by walls and the floor. These areas should always be prioritized during insulation upgrades.

Does insulation really lower energy costs?

Yes. Good insulation reduces heat loss, so heaters run less often and consume significantly less electricity or firewood over time.

Is insulation necessary for summer use?

Yes. Even in summer, insulation stabilizes temperature, reduces overnight heat loss, and protects against moisture damage from condensation.

Can I upgrade insulation in an existing sauna?

Yes. Insulation can be added during renovation by removing interior cladding, installing insulation and a vapor barrier, and reinstalling the interior wood.

What happens if insulation is installed incorrectly?

Poor sealing, compressed insulation, or missing vapor barriers can trap moisture inside walls, leading to mold, wood rot, and structural damage.

How often should insulation be checked?

Inspect insulation performance visually once a year and after severe winters. Look for condensation, cold spots, or rising energy use.